Have you ever dreamed of working in the automotive business? Creating new luxury limousines, self-driving or autonomous cars? Then you'd better upgrade your CV and send it to the HR department of Tesla, Toyota, or, maybe, Daimler. Practically all giants and indie brands are rushing towards implementing new horizons that AI in automotive applications promises to expand.

This article will look closely at the modern AI-powered auto industry to see what Artificial Intelligence technologies have already been integrated there and what challenges for innovations exist.

WRITTEN BY:

Aliaksei Sliborski

Senior Software Developer, Qulix Systems

Contents

AI in Automotive — Face the Challenge

First, let’s see how popular AI is in general in the manufacturing industry. According to Valuates Reports, the size of the global Artificial Intelligence market in manufacturing is expected to reach USD 4,798 million by 2026, with a CAGR of 28.1% during 2021-2026. It indicates a constantly growing demand for Artificial Intelligence from manufacturing companies in different industries. Do all industries around the world apply AI on the same scale?

Well, no. In reality, the adoption of AI is on a varying level today. In the automotive industry, the range of implementation of Artificial Intelligence is lower than in such industries as Financial Services and ICT, Retail, Healthcare, and Industrial Machines sectors. AI in the automotive industry is categorized as “a new adopter,” showing that there are plenty of goals for Artificial Intelligence to attain. So, let us see what can be achieved by AI in automotive.

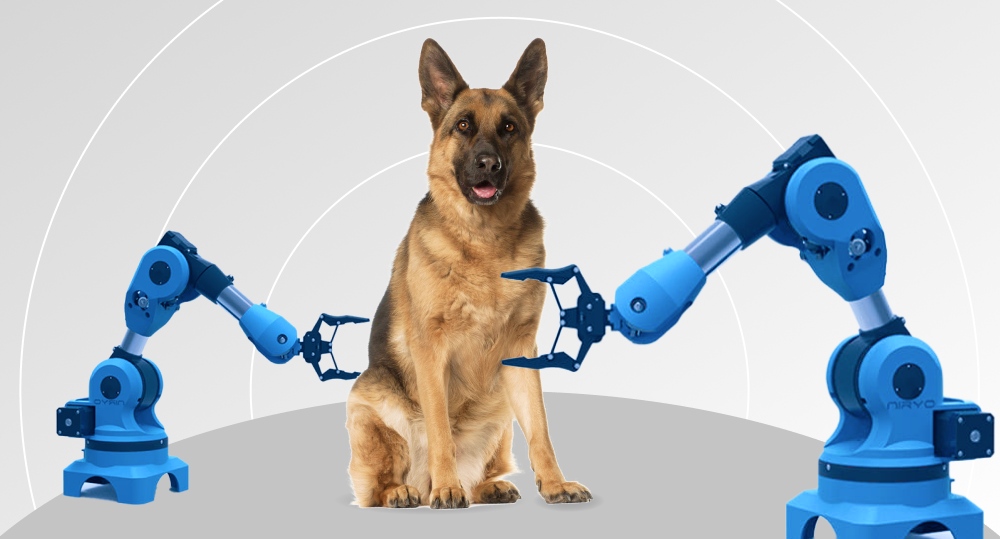

Collaborative Systems — All for One

For example, the European giant Groupe PSA is working on its project of an “excellent plant,” where they are pioneering the use of the most advanced AI technologies, Machine Learning, collaborative robots, and other innovations as intensely as possible. Their upgraded plants will improve overall technical performance and significantly reduce costs for the whole manufacturing process.

The workspaces of the group have already implemented some of the advantages of Artificial Intelligence and Machine Learning. The quality control system on different manufacturing stages operates automatically using sensors, computer vision, and AI algorithms, and after that, the products get the approval of the operators. Data from robots and assembly lines are constantly collected and analyzed using AI for real-time monitoring and, if necessary, fast troubleshooting.

The manufacturer successfully integrated UR10 — a robot by Universal Robots — into the production site in Sochaux, France. Such robots “work” in an assembly line alongside people. They perform monotonous, repetitive mounting tasks and use sensors to monitor their human co-workers’ actions. The algorithm looks for anomalies in performance and activates robots’ responses in real-time. This collaboration significantly reduced the time of manufacturing and also increased safety during the mounting process.

Autonomous Drones — Air Support

One more way to enhance productivity — to use drones in the supply chain. The Spanish automotive company SEAT incorporated autonomous drones with computer vision and AI applications in its environment. Partnering with Grupo Sesé, they implemented a project to deliver car parts to the manufacturer assembly workshop from supply chain warehouses.

The drone delivery protocol is activated when a specific part is required in the assembly line. The request is sent to the Grupo Sesé Logistics Centre, where they load an industrial drone, and then it autonomously flies a 2-kilometer distance to the SEAT factory. The drones use computer vision and AI systems to cover the route at the height of 95 meters flying at 40 km/h. The whole process takes only 15 minutes. The car manufacturer is sure that drones will improve logistics in the factories by 80%.

Now let us look at one more important perspective for AI in car manufacturing — augmented and virtual reality assistance.

Augmented Reality — AI Insider

Innovative vehicle industrial development, quality control, and testing in the smart automotive industry need rethinking — they require more than studying sample objects. BMW uses the advantages of Artificial Intelligence in augmented reality for various processes in their production chain, which significantly saves costs, time, and effort and provides new opportunities for developers and engineers of the brand.

The collaboration with Epic Games — a video game developer — helped create a unique mixed reality system. The basis of this system is Unreal Engine, developed by Epic Games. Artificial Intelligence in Unreal Engine empowers engineers with a new level of flexibility to interact with objects in virtual reality.

This smart gaming technology was actively used to develop the BMW iX model. For example, while taking a journey over a virtual city, the engineers tested visibility around the car, altering seating positions. Presenting vehicle functions and interior innovations through virtual visual experiences, developers could simulate the driving experience in different avenues and create a smarter driver-oriented car.

You see that implementing AI in automotive provides huge perspectives for car manufacturers. Meanwhile, it helps bring the driving experience of users to the next level. Catch up with some following exciting examples.

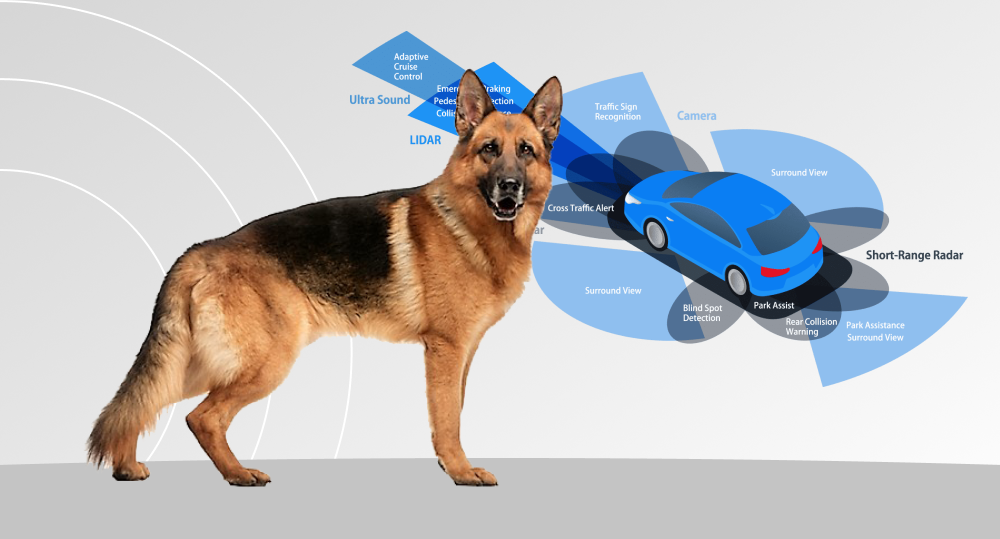

Driver Assistance — At Your Service, Sir

AI-powered advanced driver-assistance systems (ADAS) bring driving experience to an entirely new level. Let’s turn to one of the biggest luxury car brands — Daimler Group. They are using a massive set of the latest innovations to shape the new smart mobility of tomorrow. Artificial Intelligence in the automotive industry, in their opinion, provides great perspectives for innovations. And among all their latest projects, the conception of advanced driver assistant experience plays a significant role. The philosophy “the car has to be a step ahead of a human” is shaping the Daimler researchers’ ideas. The 2021 Mercedes-Benz S-Class series uses all the benefits of digitalization to provide the driver with the latest achievements in advanced assistance.

Intelligent Drive assistance technology collects traffic data employing cameras and sensors and carefully supports the driver in real-time using AI. The system has numerous functions such as Traffic Sign and Active Distance Assists (to determine traffic environment), Active Steering, Braking, Parking, Blind Spot, and Active Lane Keeping Assists (for the best performance on the road).

The extra option Drive Pilot promises a new experience of relying on Artificial Intelligence self-driving mode. Drive Pilot will enable new S-Class cars to take over some driving tasks for Level 3 automated performance. For example, in Germany, the laws allow assisted performance on some motorways with high-density traffic and restricted top speed at 60 km/h. While activating Drive Pilot, drivers can check the news or work and rely on the AI systems of the car. Meanwhile, the drivers are monitored by the system and not allowed to sleep or leave the car because they must always be ready to take over the control of the vehicle.

The brand also offers the next generation of MBUX — the multi-system of onboard AI-powered assistance — that delivers a new stage of personalization and interaction for the driver and the passengers with an individually mounted set of technology for each seat. That assistance goes further than personalization and entertainment.

New Standard for Safety — AI Never Sleeps

Beyond advanced personalized performance, AI systems in automotive are responsible for the new upgraded approach to safety standards. Adopting AI and Machine Learning technologies into various systems for detecting, warning, and preventing accidents is now a norm for all car manufacturers. It started in 2015 when Toyota introduced the new trend of AI in automotive — Toyota Safety Sense technology for its cars. It was a revolutionary set of electronic safety equipment for driver assistance, and later this idea was followed by other companies.

The new generation of Toyota Safety Sense™ (TSS) 2.0 comes as a standard in many of the company’s latest models. The system has several active safety features working for one important goal — avoiding as many accidents as possible and diminishing the effects of accidents impossible to prevent.

The TSS 2.0 suite consists of six integral features — Pre-Collision System and Pedestrian Detection, Road Sign and Lane Tracing Assist, Lane Departure Alert and Steering Assist, Dynamic Radar Cruise Control, and Automatic High Beams. The features are based on two primary in-build sensors — a single-lens camera under the radiator emblem and a millimeter-wave radar. But the main component, the brain of TSS 2.0, is the vehicle’s computer processor that analyzes the incoming data and immediately produces decisions based on AI algorithms. The system does not only inform the drivers but also accompanies them. For example, if it determines that the vehicle deviates from its lane unintentionally, it gives audible and visual warnings. Then, it may activate automated correcting steering inputs to help the driver stay in the lane and avoid accidents.

Bottom Line

Undoubtedly, the automotive industry is not only a smarter factory but a new approach to engineering and design and advanced solutions for driving assistance and safety. Forward-minded automotive business requires updated algorithms for marketing, insurance, maintenance, connected vehicles solutions, and other projects. Artificial Intelligence knows answers for all these "extra" challenges. We should also mention that our dedicated AI cluster is ready to extend your business capabilities with the best Artificial Intelligence solutions.

For more info about Artificial Intelligence as a Service, contact our specialists. And do not forget to follow our blog to stay up to date about the latest AI innovations.

Contacts

Feel free to get in touch with us! Use this contact form for an ASAP response.

Call us at +44 781 135 1374

E-mail us at request@qulix.com